Isodiametric tractors, reversible, with double steering system. 73 or 91 HP

The Vega V80 and V95 Dualsteer® are specialized tractors with the exclusive double steering system. The Dualsteer® combining safety and stability of the steering wheel ‘RS’ version with the performance in curves and manoeuvrability of the ‘AR’ version with central articulation.

The standard reversibile driving position, the short wheelbase and the steering radius to 2200 mm. only (with wheels 280/70-18) make the Vega V80 and V95 Dualsteer® the ideal machine to be used both on slopes and in the most extreme conditions, where the ability to move with ease and in total safety becomes the only way to work: vineyards and orchards with narrow row spacing, greenhouses as well as all the maintenance works, both in summer and winter, typically done by local municipalities.

Two VM engines are available for the Vega: a 73 HP four cylinder engine (Vega V80) and a 91 hp four cylinder engine (Vega V95), both with counter-rotating mass and EGR System.

The decision to use a lower number of rpms, 2,300 rpm/min was conceived to reduce consumption, noise level and vibrations, with the benefit of comfort.

The EGR System located inside the engine allows to reduce the emissions of nitrogen oxides and fuel consumption.

- General Details

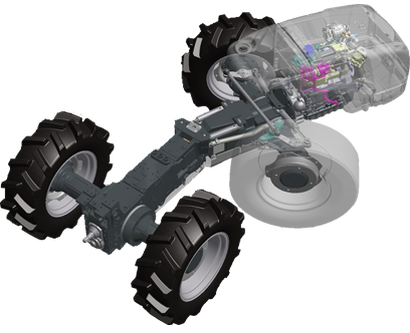

Model Engine Power KW/HP Nominal speed (rpm) No. of cylinders Displacement (cm3) Aspiration Maximum torque (Nm/rpm) VEGA V80 VM D754 TE3 53.7 / 73 2300 4 2970 Turbo 250 / 1600 VEGA V95 VM D754 IE3 67 / 91 2300 4 2970 Turbo Intercooler 420 / 1000 - DUALSTEER SYSTEMThe Dualsteer® is a patented double steering system that combines the central articulation of the frame with the steering of the front wheels: this allows to realize a real steering angle equal to 70°.

From the operational point of view the driver only needs to operate the steering wheel because the control of the engagement proportionality of the two devices, which act simultaneously, is guaranteed by a hydraulic circuit and by a specific system of mechanical connection of synchronization. The hydraulic circuit acts both on the steering cylinders of the central articulation and on the steering cylinders of the front wheels while the connection system guarantees the synchrony and the progressiveness of the steering.

The additional hydraulic cylinder on the central steering increases both the power steering with high accuracy at very low speeds also in presence of high load on the axles, both the direction and stability on road transfer at high speeds.

- TRANSMISSION AND GEARBOX

The Vega are provided with OS-Frame transmissions: a unique transmission shaft moves both the gearbox main clutch and the PTO independent clutch, while assuring the best mechanical output.

The joint in the middle of the machine lets the front axle oscillate up to 15° with respect to the rear axle, for excellent stability on slopes, as the four wheels are always stuck on the ground.

The 32-speed synchronised gearbox (16 FWD + 16 REV) with synchronized reverser always allows right gear selection for the tasks for which the tractor is intended to.

The ‘Long Life’ clutch is multidisc in oil bath with a proportional hydraulic control and Pro-Act System for maximum performance and comfort.

The Vega are equipped with planetary gear axles to minimize wheelbase of the tractor and increase its manoeuvrability.

The 4-wheel drive has got an electro-hydraulically controlled disengagement of the front one.

- PTO AND HYDRAULIC SYSTEM

The rear PTO is independent from the gearbox and synchronized with all progress speeds. PTO can be engaged by an electro-hydraulic control, it has a speed of 540/540E rpm or, as optional, 540/1000 rpm. The clutch is multidisc in oil bath.

The solid rear hydraulic lift by rams (optional with position and draft control) relies on multi-purpose practical and versatile couplings to adapt quickly and easily to all marketed equipments.

As optional, it is also available a hydraulically controlled upper link and tie rod which allows adjusting the attachments from the driver’s position, and a performing front lift which is necessary when using combined attachments.

The hydraulic system consists of a double circuit with two independent pumps and dedicated heat exchanger: the hydroguide pump has a flow rate of 28,5 l/min, like the one for the lift and distributors. As optional a 49 l/min oversize pump is available.

A joy stick with electronic control (optional), is used to control both the hydraulic system and the rear lift with a single device.

- ACTIVE AND PASSIVE SAFETY

The braking system, with 4 multiple disc wet brakes, is assisted by an hydrostatic control acting as braking distributor which intervenes constantly and simultaneously on the 4 wheels when acting on the pedal.

Exclusive to the Vega is the independent Brake-off parking brake that is automatically inserted when the engine is off. When the unit is operating, on the other hand, it is controlled with a practical button on the dashboard.

The electro-hydraulically controlled front and rear differential lock, simultaneously or rear only, assures the best traction on any type of grounds.

The roll-bar and the safety belts on the seat protect the operator.