The new electronically-operated Stage IIIB engines comply with the strictest European standards as for emission control: a supremacy among isodiametric tractors translating into lower consumption, less toxic emissions and higher operating comfort.

Innovative technical content, elegant design and reduced overall dimensions make Vega K105 and L80 indispensable machines for future agriculture.

- General Details

Model Engine Power KW/HP Nominal speed (rpm) No. of cylinders Displacement (cm3) Aspiration Maximum torque (Nm/rpm) VEGA L80 Kohler KDI 2504 TCR 55.4 / 75.3 2300 4 2482 Turbo Intercooler 300 / 1500 VEGA K105 Kubota V3800 CR-TE4 72.1 / 98 2400 4 3769 Turbo 330 / 1500 - DUALSTEER SYSTEMVega K105 and L80 tractors have a matchless manoeuvring capacity, thanks to their short wheelbase and their compact dimensions.

The steering wheel is power assisted, through a dedicated hydraulic system. The manoeuvres are precise and the turning radiuses are very small both in models with steering wheels and in those with central joint, and especially in Dualsteer® versions.

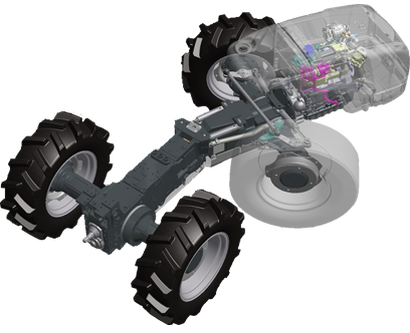

Dualsteer® is internationally patented and is unique on the market: it is a double steering system joining the central joint of the frame to the steering of front wheels, the steering angle can reach 70°

- TRANSMISSION AND GEARBOX

Engine and clutch are reciprocally connected by a single shaft transmitting movement both to the gearbox main clutch and the PTO clutch, obtaining compact dimensions and larger steering angles.

A joint in the middle of the tractor give more stability on slopes and all soil conditions, keeping the highest traction on all four wheels.

The synchronised gearbox is formed by 4 ranges and 4 speeds, for a total of 16 ratios both in forward and reverse, with synchronised reverser.

The logic sequence of speeds (from 700 m/h to 40 km/h) allows the selection of the best gear for the required use, with following fuel saving, reduced stress on mechanical components and a better quality of the work.

The new electronically-managed multiple-disc clutch in oil bath is smoother to engage and more performing vs the standard dry clutches, so that the operator can control the tractor always with more precision.

The use of this evolved hydraulic clutch inside the transmission generates a series of concrete advantages: longer life, no maintenance and top manoeuvrability thanks to the more compact dimensions of the tractor.

The clutch engaging pedal comes with the Pro-Act System for a more comfortable and ergonomic movement of the foot on the pedal. The operator is more sensitive to modulation.

- PTO AND HYDRAULIC SYSTEM

The rear PTO, with multiple-disc clutch in oil bath is independent from the transmission and is synchronised with all progress speeds.

The sturdy rear lift has a lifting capacity of 2300 kg; for SDT differentiated wheels versions it’s 2700 kg.

A performing front lift is available as an optional, indispensable for using multipurpose implements.

The hydraulic system has two circuits with independent pumps and heat exchanger for oil cooling.

The oversized flow rate of pumps allows all modern implements for specialised agriculture to be coupled.

- ACTIVE AND PASSIVE SAFETY

The use in full safety both slopes and crosswise is guaranteed by the design geometry of Vega K105 and L80 tractors, having a low centre of gravity and a very good weight distribution on axles when the implement is coupled to the rear lift.

The differential lock is electrohydraulically operated, so that the tractor is always under traction.

Four disc brakes in oil bath intervene simultaneously and continuously on all four wheels, even when the front drive is released, as they are supported by a hydrostatic control acting as braking divider.

The independent Brake-off parking brake is exclusive to Vega range: it automatically engages when the engine is switched off.